Soundboard (Pt. 3)

Although this guitar would be classified as a flattop instrument, the top really isn’t completely flat. The braces on either side of the bridge have a small curve built into them. This gives the soundboard a slightly domed profile, which makes it stronger than if it were absolutely flat. That means I can make the soundboard a little bit thinner and not have to worry about how it will resist string pressure over time. Here is a picture of the soundboard with a wooden straight edge resting on it to show how much of a dome is built in. It’s about 1/16″ from the center to the edge.

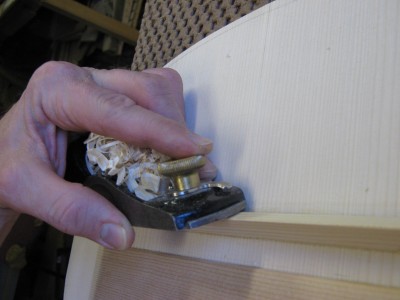

After all of the braces are glued, they have to be shaped and tapered in order to get the best possible tone and responsiveness from the completed guitar. The braces on this instrument will have a triangular profile because that is what the Stella 12 String guitars had. Below are a couple pictures of braces being planed to the shape and height I want them to have. I’ve also included a picture that shows the profile of the completed braces.

I determine the final height of the braces by periodically tapping on the soundboard as the braces are being planed. I can’t describe what I’m listening for very well, but I do know when I’m hearing what I want to hear. I’m not listening for any particular musical note, just how the soundboard vibrates. It changes quite a lot as wood is removed from the braces.

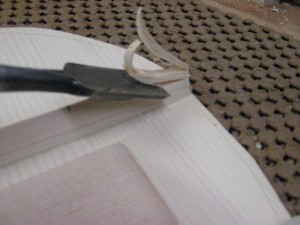

Once I have the braces where I want them, the ends are scooped with a chisel. This frees up the soundboard to allow more vibration around the perimeter of the guitar. The perimeter area is naturally stiffer than the center of the soundboard, so the braces don’t need to be the same height/stiffness as they are toward the middle.

The next step is to trim the braces to length and mark where they will meet the sides. The kerfed lining on the sides is then chiseled away where the braces will sit. The missing sections will be replaced later. Here’s a picture of the notched out kerfing:

The braces and the spruce soundboard are sanded to 220 grit, then it is time to glue the soundboard to the sides. Here is one more picture: